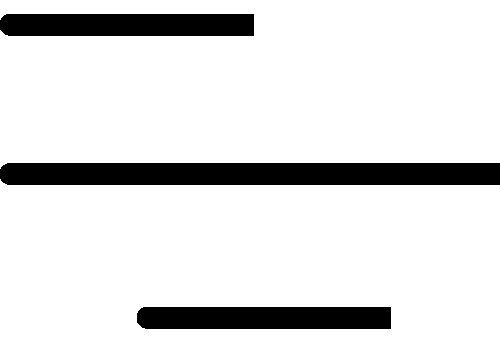

Electrostatic Precipitator

Ideal for commercial kitchens, industrial plants, and power generation facilities, they ensure cleaner air and a safer environment.

Technology

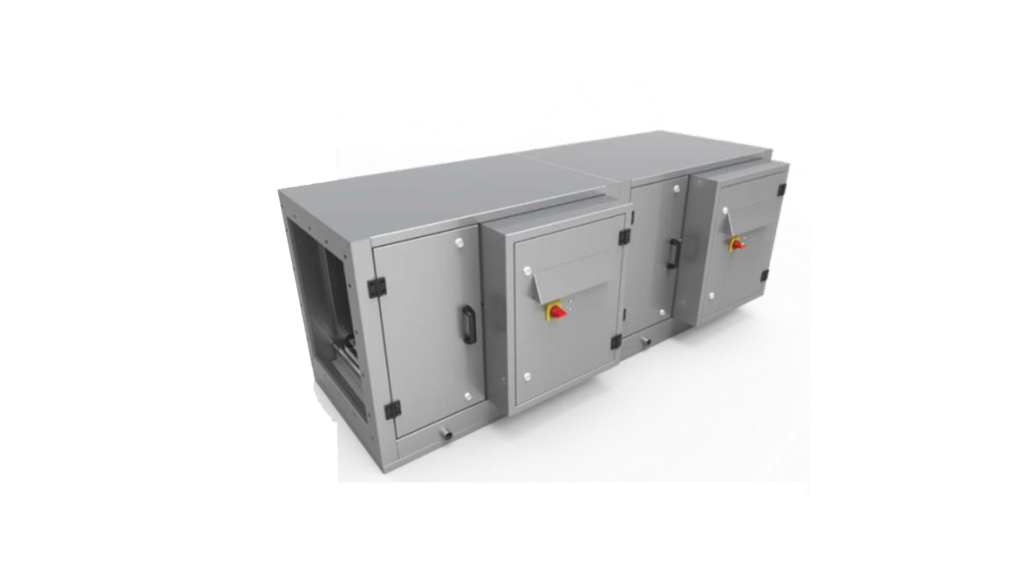

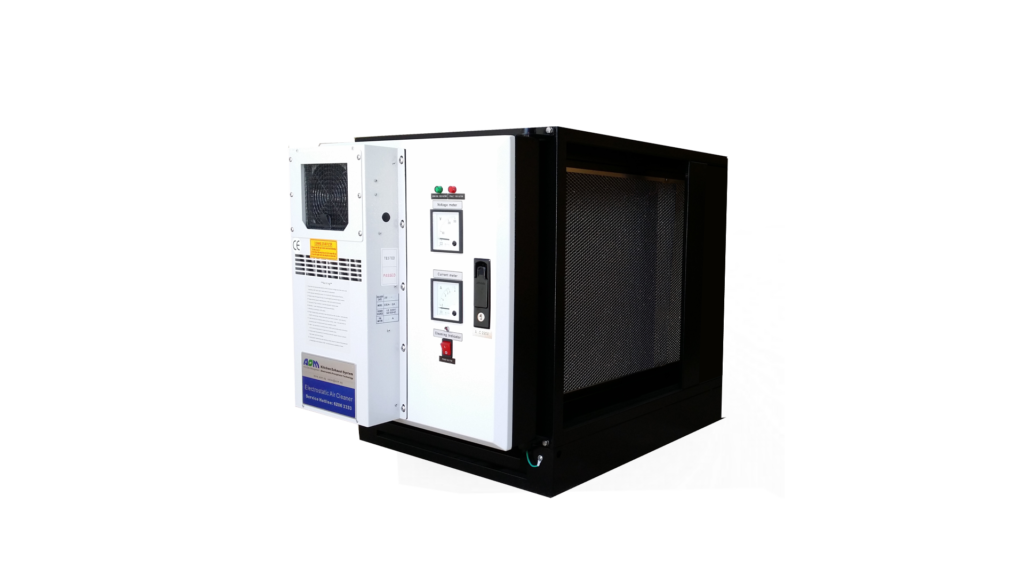

Electrostatic precipitation operates in three distinct phases. First, central cathode needles positively charge the smoke and grease particles in the air stream. To make sure that our products are the most effective and efficient pieces of equipment available on the market right now, we are constantly improving them.

- The cathode needles are placed in the middle of the cylindrical anode collectors. This guarantees a stable, strong, and enhanced ionisation field.

- While traditional ESP technology typically permits an inlet velocity of only 3 to 4 m/s, Green Crystal’s Electrostatic Precipitator can handle up to four times that rate, setting a new performance benchmark.Our units can operate at velocities of up to 15 m/s without compromising efficiency or effectiveness.

- In contrast to other filtration systems, Green Crystal ESP consumes energy solely for contaminant removal, resulting in a minimal drop in air pressure.

- By eliminating big particles and promoting uniform airflow throughout the cells, a flow-equalization plate boosts productivity.

- To further improve air quality, our systems generate ozone that neutralizes kitchen emissions and unwanted odours.

- Superior mechanical strength enables the unit to withstand frequent cleaning and long-term industrial use.

Got Questions? We’ve Got Answers

Frequently Asked Questions

Explore our FAQs to learn more about our Electrostatic Precipitators and how they improve your ventilation systems.

Electrostatic Precipitators can be used in power plants, cement factories, steel mills, and pulp and paper industries. They are used in industrial boilers, petroleum refineries, and chemical manufacturing units. They help control particulate emissions in thermal power stations and incineration plants.

ESPs are effective and capture extremely fine particles such as smoke, oil mist, grease, dust, and other airborne pollutants. They help maintain cleaner indoor air quality and a safer working environment.

Compared to traditional filtration systems, Electrostatic Precipitators use significantly less energy. As a result, they consume minimal power while maintaining excellent particle removal efficiency, making them a highly cost-effective solution for air purification.

Yes. Our Electrostatic Precipitators are designed to meet both national and international air quality and emission standards. Consequently, this helps businesses stay compliant with regulations while contributing to a cleaner and healthier planet.

GreenCrystal stands out because of its advanced filtration design, superior particle collection efficiency, and durable construction. Our systems combine innovation with reliability, delivering cleaner air, quieter performance, and longer operational life compared to conventional ESPs.